By submitting your email you agree to receive information about relevant products and services. You may unsubscribe at any time. Read our Privacy Policy here.

Geometric dimensioning and tolerancing (GD&T) is a system of symbols used on engineering drawings to communicate information from the designer to the manufacturer through engineering drawings.

GD&T tells the manufacturer the degree of accuracy and precision needed for each controlled feature of the part. GD&T is used to define the nominal geometry of parts and assemblies and to define the allowable variation of features.

Common GD&T Symbols

Modifiers

Tolerance Zones

Feature Control Frames

| Symbol | Geometric Characteristic | Feature Modifier | Datums | Datum Modifier | Bonus Tolerance | ||

|

Form

|

|

Straightness | ✓ |

Datums Not Allowed

Form tolerances are defined to limit the deviations of a geometric feature from its ideal form.

|

NA | ✓ Only at MMC or LMC | |

|

Flatness | X | NA | X | |||

|

Circularity | X | NA | X | |||

|

Cylindricity | X | NA | X | |||

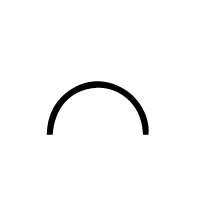

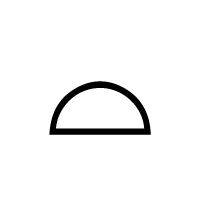

| Profile |  |

Profile of a line | X | Datums sometimes required | ✓ | X | |

|

Profile of a Surface | X | ✓ | X | |||

|

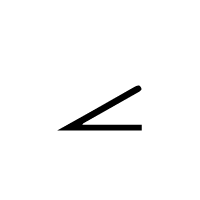

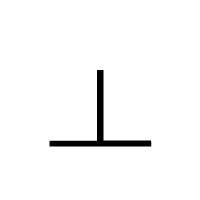

Orientation

|

|

Angularity | ✓ |

Datums Required

|

✓ | ✓ Only at MMC or LMC | |

|

Perpendicularity | ✓ | ✓ | ✓ Only at MMC or LMC | |||

|

Parallelism | ✓ | ✓ | ✓ Only at MMC or LMC | |||

|

Runout

|

|

Circular Runout | X | X | X | ||

|

Total Runout | X | X | X | |||

|

Location

|

|

Position | ✓ | ✓ | ✓ Only at MMC or LMC | ||

|

Concentricity | X | X | X | |||

|

Symmetry | X | X | X | |||

If no modifier follows a datum feature size, the datum feature applies regardless of material boundary.

|

Specifies the type of zone applied to the tolerance.

|

In GD&T (Geometric dimensioning and tolerancing), a feature control frame is required to describe the conditions and tolerances of a geometric control on a part's feature. The feature control frame includes four parts:

Combined, the feature control frame provides all the information you need to measure the geometric tolerance of the features of the part and determine if the part is in spec.

Need to use GD&T fonts in Excel for your inspection reports? Download our free GD&T font and reference guide.

What’s Included:

Need to use GD&T fonts in Excel for your inspection reports? Download our free GD&T font and reference guide.

What’s Included:

See how you can automatically balloon GD&T callouts to create feature control frames.

Copyright 2025 InspectionXpert Corporation, is a wholly owned subsidiary of Ideagen Inc, All Rights Reserved